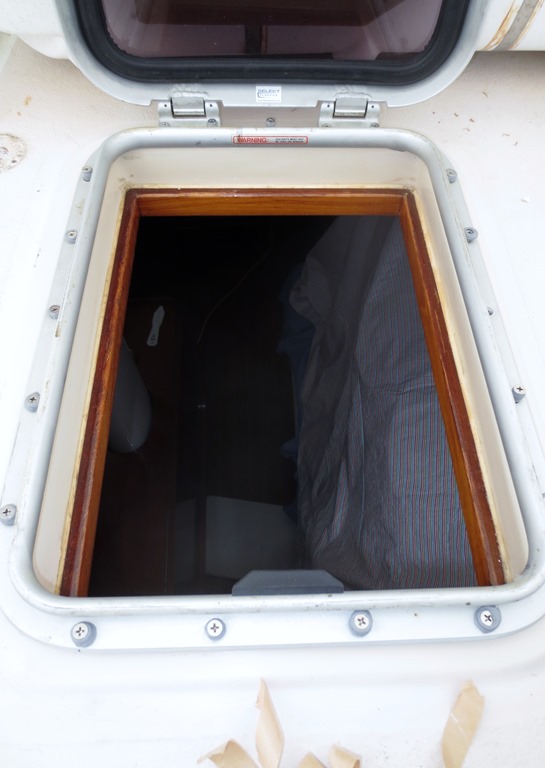

In preparation for launching Magnolia this week, “Material Condition Zebra” has been set! Material Condition Zebra is the Navy term for configuring hatches and valves in such a manner to make the ship water tight as possible.

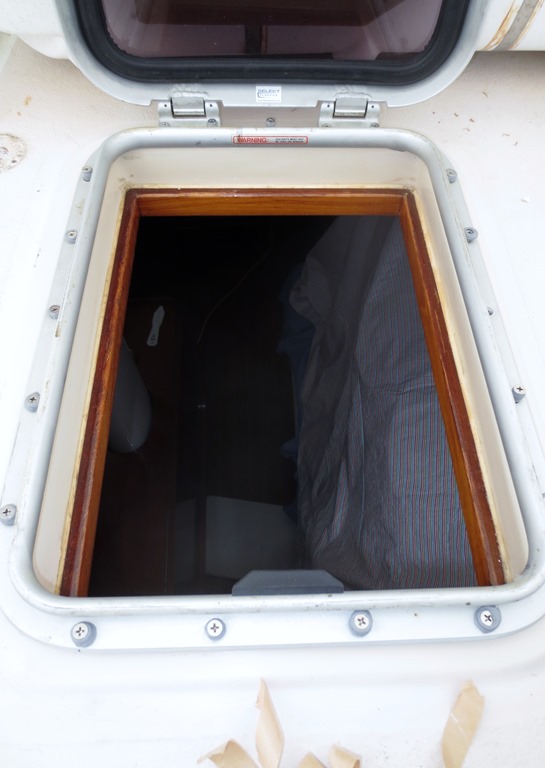

Magnolia has 11 deck hatches in over this last winter they were shipped to Select Plastics in East Norwalk, CT in groups of 5. Turn around time approximately 5 weeks and the work was completed as promised and on time. They replaced the lenses, gasket seals and performed other maintenance as required.

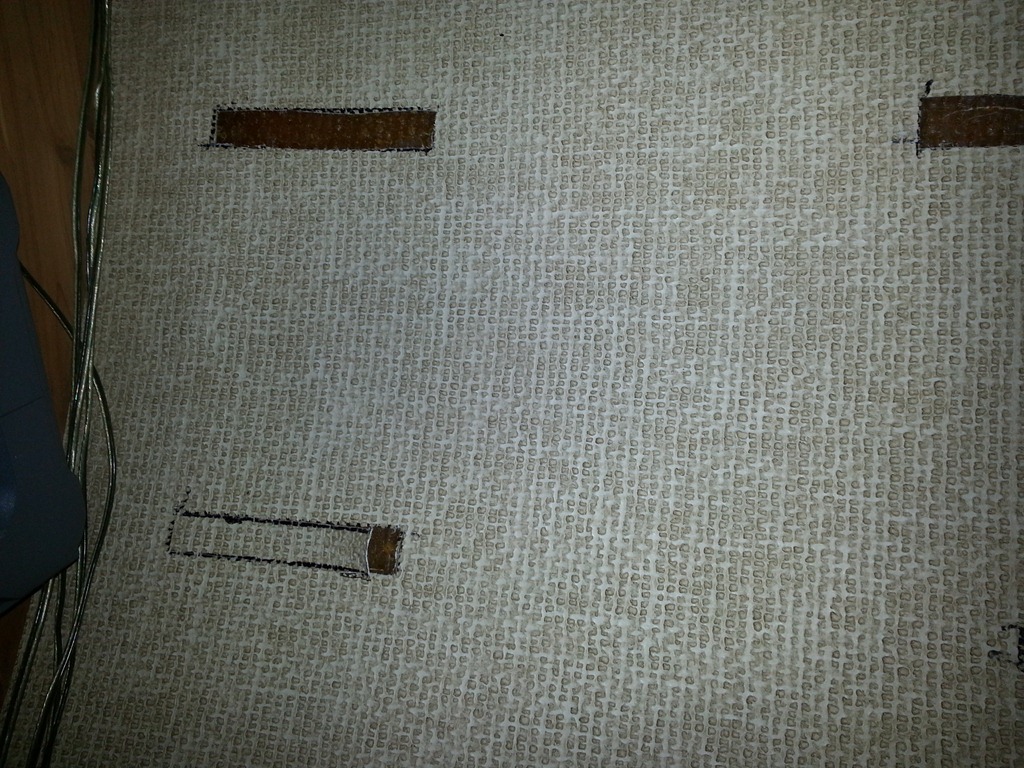

I used a Butyl tape to provide a gasket seal for the frame and individual screws. I applied 3 –4 layers of tape to the frame leaving the backing tape to the last layer applied.

I also applied a wrap of Butyl tape to each of the screw heads. I was able to complete the application of the Butyl tape at home. The screws were placed on wax paper for easy transport to Magnolia for installation.

Once “onboard” I used an ice pick to punch a hole through the Butyl tape and the backing tape. Yes there was a drop of blood shed as can be seen. Come on, you give me an ice-pick I am certainly good for at least one wound!

I then used a couple of ice picks to align the frame to the mounting holes BEFORE removing the backing tape! BEFORE removing the backing tape!! You have been warned!

Once the holes were all aligned the backing tape was removed the the individual screw inserted. Do not press down the frame firm yet.

The frames were checked for any gaps and an additional bead of Butyl tape for pressed under the frame for using an ice pick.

The secret to successful use of Butyl tape I am told is slowly compressing the seal. I gently snugged up all the screws applying equal compression all around to the Butyl tape. I will repeatedly snug the screws down during our next couple visits to the boat.

In addition to getting the hatches installed, Annette cycled and ensured each of the thru-hull valves were left in the closed position. With that, Magnolia is ready for re-launch this Thursday!!