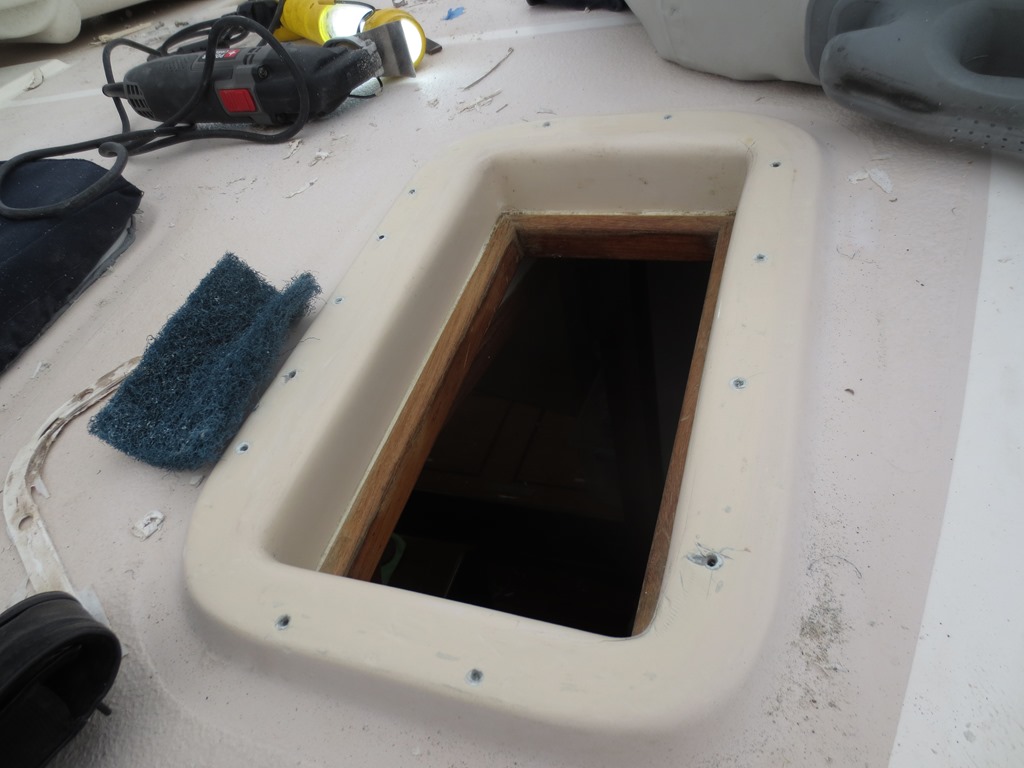

I know it has been a while since my last post but that should be not be taken as an indication of tasks not being completed! The big speed bump on the “critical path” to getting Magnolia underway for Memorial Day Weekend (our short term goal) is getting the cabin top hatches back from overhaul and re-installed. Obviously we can’t remove the shrink wrap until the hatches are re-installed. In addition we can not finish sanding the the port side toe rail until the shrink wrap has been removed. That leads to not being able to varnish the port side toe rail until it has been sanded. If you can not varnish the cap rail you certainly cannot install the life line stanchions on top of the toe rail. If the lifeline stanchions cannot be installed, you cannot measure for the new lifelines. If you cannot measure for the new lifelines, cannot order new ones from the fabricator. Until you order new ones, wait for fabrication and then install them, we you cannot go sailing (safely) on Memorial Day weekend… See how those hatches are holding everything up?

Admiral over seeing hatch removal

In the mean time we have taking care of all those onesy and twosys tasks. Annette has completed making all new curtains, duvet for the bunk and a plethora of very cool throw pillows. George (ZZ Top’s twin) has finished the cockpit enclosure and called last evening to let Annette know the Settee Cushion recovering is complete. (If you need a canvas guy, George is GREAT!) Bayshore Marine has finished the engine and generator maintenance and Shiver Me Timbers should finish the refrigeration this week. I still have some glue, varnish and shelf installation in the aft cabin but there is time for that!

Bottom line, things are coming along as best as we could hope for! As soon as we can get the hatches off the Critical Path, we will have much better control of our destiny!!