We had to order sanitation hose so that left today open to take on another project that has been waiting in the wings. Hatch restoration. Sailboats are notoriously dark so as much light as you can get “down-below” is all the better. The “windows” in the hatches are made out of plastic and after some years they become crazed and look unsightly. In addition the gaskets wear out eventually as well. We have old Lewmar Rollstop Hatches which they only made for 4 years so that should tell you something! They are what we have and because of their unique sizes it is not economical to replace them. That said the best we can do is have them rebuilt by the experts at Select Plastics.

All things considered this is the perfect time to have the work down in that the boat deck is completely covered by the shrink wrap. On a sunny day like today it makes it completely comfortable to work on deck even when like today the temperatures were in the mid 30s and wind was gusting in the 30-35 knt range! The whole time I was working in shirt sleeves!!

I previously made an emergency hatch cover for each of two sizes of hatches. (2 & 4) In case of heavy weather and a hatch failure we would be able to prevent a huge amount of water from entering the boat. In addition I made them with carriage bolts only being exposed do they would provide some level of security if I needed to use them in non-emergency situations such as this. I should have take a picture from below but there are basically oak cross members cross the hatch frame below with wing nuts holding the carriage bolts.

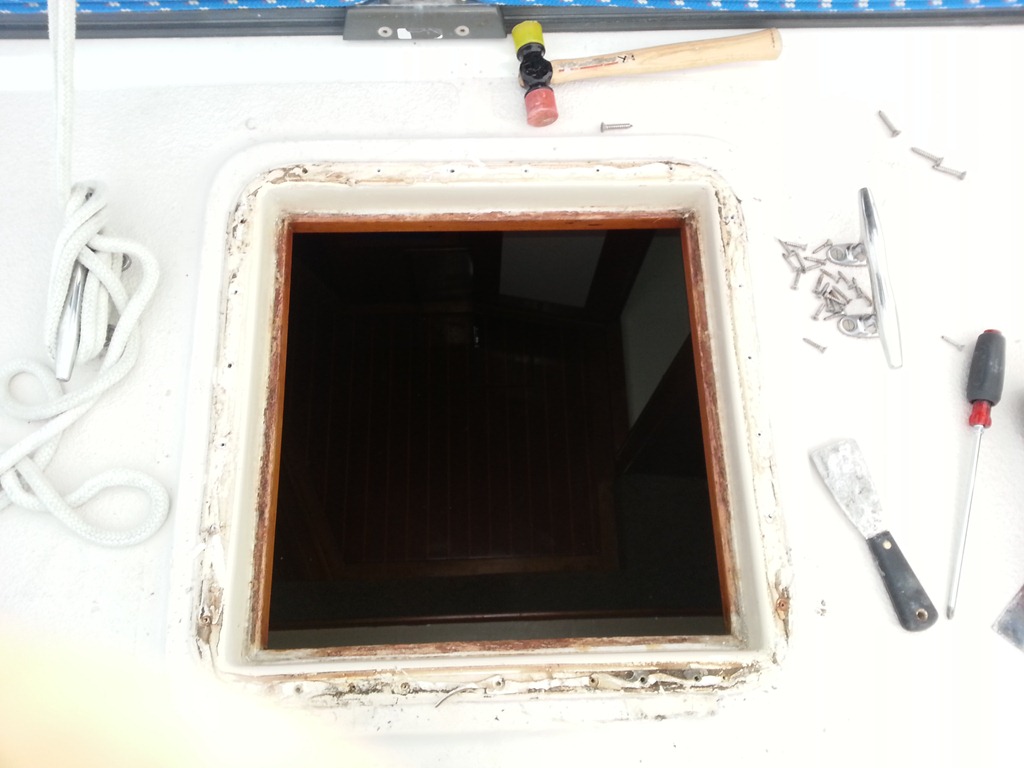

After taking the all screws surrounding the frame of the hatch it was a relatively simple matter to separate the frame from the deck suing a Plastic/Rubber tipped hammer and paint scraper with a sharpened edge. BTW – If you do not have one of these hammers, go get one now. My buddy Greg Rodgers turned me on to this one and it is no much better than a standard hammer on a boat. This hammer has saved me from inflicting real damage on Magnolia so many times!!!

Here is the aft hatch removed and all battened down with the emergency hatch cover. I will have to add a picture of below but the underside has cross members just like the top which makes for a very solid installation. (1/2 inch plywood and oak cross members all with a coat of 2 part epoxy)